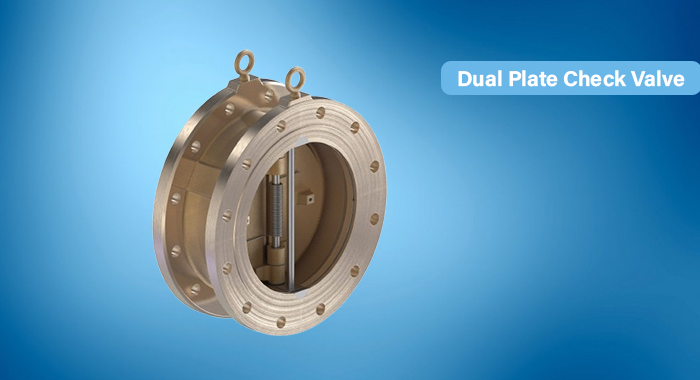

DUAL PLATE CHECK VALVES

Dual Plate Check Valves are non-return valves designed to allow flow in one direction and prevent backflow using two spring-loaded plates. Their compact, lightweight design ensures minimal pressure drop and efficient performance. These valves are widely used ins Oil & Gas, and Chemical Industries for reliable flow control.

SPECIFICATIONS

Size Range : 2" to 48" (DN 50 to DN 1200)Pressure Ratings: ASME 150# / 300# / 600# / 900#

Materials Available:

Testing & Inspection Standards: API 598

CONSTRUCTION & KEY FEATURES

Body/Bonnet Types:SPECIALIZED APPLICATIONS

Tailor-made designs for critical operations in:

Optional testing available for:

Get the Best Dual Plate Check Valve Price in India Contact us today for a quote or more technical details at info@panchvativalve.com